Glass and mirrors - A rich history

Glass history Part 1

5000 BC - AD 100

» The discovery of glass

Glass probably exists since the beginnings of time, formed as a result of high temperature .... Glass history »»

Glass history Part 2

AD 100 - Industrial Revolution

» The Roman influence

The Romans have made it possible that the knowledge of making glass could be spread so quick and in such a large area. With its conquests, trade relations, road building, ....Glass history Part II »»

Glass history Part 3

Industrial Revolution - Present day

» A craft becomes industry

It was not until the latter stages of the Industrial Revolution, however, that mechanical technology for mass production and in-depth scientific research into the relationship between the composition of glass and its physical qualities began to appear in the industry.....Glass history Part III »»

The history of mirrors

Mirrors are used by man long befor the discovery of making glass. Made of metal ....Mirror history »»

Glass and Mirrors history.

The history of glass oven - glass furnaces

For centuries, man has used fire to melt and shape all kinds of raw material.

The discovery that a fire can be used more efficiently and the temperature will be higher by using an enclosed structure, is the beginning of the development of glass furnaces.

Pit oven

Pit oven are used by man long before the christian era. It is in fact nothing more then a large pit in which the floor was covered with stones. On this pit an oven was build in which the glass could be melted.

The space beneath the oven 'the pit' was used as fireplace, mainly wood-fired. The temperature such an oven could reach was between 600 and 700 degrees Celsius.

Due to this rather low temperature the glass could not be melted entirely, it just got hot enough to become a kneadable mass.

Pot furnace - pot oven

The pot furnace was used to melt glass, since the beginning of the christian era until the late 17'th century

A simple, dome shaped stone construction with a fireplace underneath was used to melt glass. Before the glass was placed in the oven to be melted, the oven had to be heated up to a temperature close to 1500 degrees Celsius.

Loading the oven did take a long time, to ensure the mixture to melt. It could take up to 15 hours to completely load the oven.

These kind of ovens could hold 60 kg. up to an impressive 1000 kg.

To fire up these kind of ovens, a huge amount of wood was used that could be easily obtained from the landowners. In those days deforestation was not seen as a problem, landowners welcomed it due to the fact that fields were of much more profit then a forrest.

The limited means of transportation made it impossible to transport the wood necessary to fire up the ovens, over a large distance. Glassmakers were forced to rebuild their ovens nereby a new parcel wood.

Grid ovens

Gridiron ovens are build mainly on the same principle as a pot furnace. With one important difference, instead of fireing on a stone plate or the bottom of the oven, the fire was placed on a gridiron.

The ashes would fall through the gridiron, making a better ventilation possible. Due to a better ventilation, the fire reaches higher temperatures.

Due to the higher temperatures that could be reached, the mixture to melt glass did change.

Gridiron ovens were mainly used from the beginning of the 17'th century until the second half of the 19'th century. One of the reasons the fireing had to change to gridirons was the introduction of coal as a fuel for the ovens.

This type of oven did develop through the years into an oven made out of two parts. A potoven - pot furnace (with higher temperatures due to the use of a grid) that was used as melting place, and a second part in which the glass could cool down to a mass with a better viscousness to be moulded. Thus providing in a better raw material to blow glass cylinders.

By using coal as a fuel, it was no longer necessary to rebuild the oven time after time. Most ovens were now build nearby a coal mine that most of the time had a railroad in the vicinity which provided further transportation.

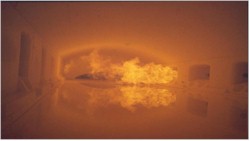

Basin- or barrel oven

Barrel oven, as they are still used in the steel industry, are made of a long stone basin with on each side burners. These burners are placed above a basin with glass and by turns are throwing their flames over the glass. The heat of the flames is used to melt the glass.

This type of oven (also called Siemens-Martin oven), were developed by Friedrich Siemens and used from the midst 19th century.

The fumes are transported through a space on each side of the oven. To prevent cold air from pouring into the oven, those spaces were filled with stones that are heated by the fumes. The cold air flowing into the oven is conducted along those stones and preheated.

Basin- or barrel oven are superior to pot oven by;

- a larger capacity of 2500 tons or more,

- a continuos production, no long loading times,

- a better regulations of the temperature,

- less fuel use,

- a permanent location and,

- no more need for wood.

In a mechanical production process the continuos availability of a large mass of molten glass is essential. Without the development of the basin oven, a mechanisation in the glass production would not have been possible.

A basin oven was, in those days, a very big investment, that could only be done by large company's and therefor we see the rise of a number of large glass industry's in that period in time.

The first Dutch float glass factory "De Maas", was build in Maassluis at the beginning of the 20th century (1910 - 1925). Here, for the first time in Holland, a gas heated basin oven was used to manufacture glass by using the Fourcault-system.